Product information

- Type: VALVE

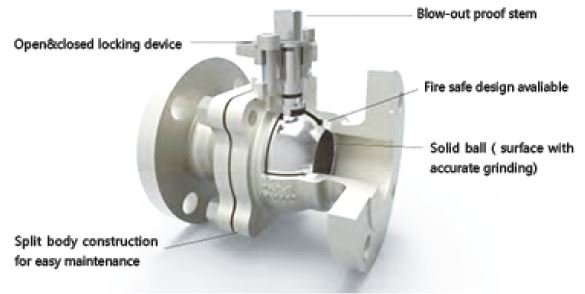

About FLOATING BALL VALVE

FLOATING BALL VALVE

Material : Cast Iron, Alloy Valve with Titanium, GR5 Zirconium, Nickel Alloy, Hastelloy, C276 Monel, 400 Incolloy, 625 Alloy, Super Duplex

Applicable Seat Material : PTFE, RPTFE (15% Glass Filled), RPTFE (25% Carbon Filled), PEEK, Nylon, Devlon, PPL, Other Request

Available : Floating Ball Design, Side-Entry, Splid Body (2-PC & 3-PC), Full Bore/Reduce Bore, Blow-out Proof Stem, Locking Device, Soft Seats, Anti-Static Device, Fire Safe Design, ISO Mounting Pad, Self Cavity Pressure Relief,

Connection : Flange ANSI, Wafer, NPT Threeaded B1.20.1, Butt Well ASME 16.25, Socket Well ASME B16.11, BSPT BS21.

Operation : Lever, Gear, Electric, Pneumatic, Actuator, Bare Shaft.

Standard : ASME B16.34, API 598, API 6D, ASME B16.10, ASME B16.5, ASME B16.34, MSS-SP-55

Size/Pressure Produce Range :

- #150LB : 1/2" up to 10"

- #300LB : 1/2" up to 10"

- #600LB : 1/2" up to 6"

- #900LB : 1/2" up to 3"

- #1500LB : 1/2" up to 2"

Features

- Robust engineering design

- Self relieving seat technology

- Patented stem seal technology

- ISO compliant bonnet

- Multiple end connections (Threaded, socket weld, butt weld, custom)

- High quality

Benefits

- Very long service life

- Bi-directional in hazardous media service

- Low fugitive emissions

- Bubble tight shut off

- Automatable

Specifications

| Size range | 1/2” – 21/2” (DN 15 – 65) standard port 1/2” – 2” (DN 15 – 50) full port |

| Temperature | 260 °C / 500 °F |

| Pressure rating | ANSI Class 800 or CWP to 2500 psi (172 bar) see literature |

| Materials | Carbon Steel, Stainless Steel, Monel, Hastelloy C materials |

| Standards | Meets ISO-15848 and other emissions standards |